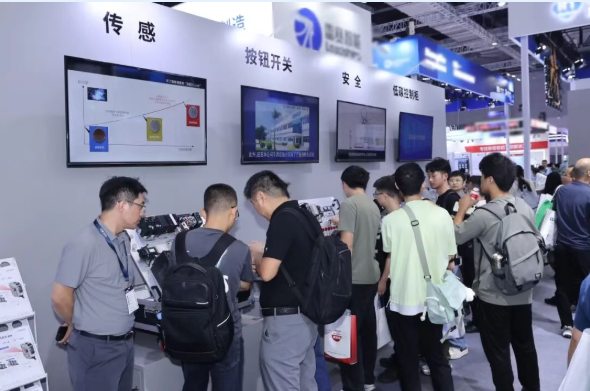

Facing multiple challenges in the manufacturing industry, such as high-mix low-volume production, energy efficiency management, full-process quality traceability, and talent structure transformation, Omron Automation (China) Co., Ltd., a digital transformation expert in the global automation field, systematically demonstrated its cutting-edge technologies and solutions that drive new quality productive forces through "Digital-Intelligent Integration" at the recently opened 25th China International Industry Fair. At this year's CIIF, Omron prominently featured three core exhibition areas: Intelligent Innovation Applications, Digital Driving the Future, and a Strong Product Matrix, presenting a feast of intelligent manufacturing for the industry. This aims to help Chinese manufacturing address real-world challenges and integrate into the industry trend of deep integration between digital transformation and artificial intelligence.

Focusing on Flexible Production, Showcasing New Breakthroughs in High-Speed, High-Precision Control and Intelligent Management

At the exhibition site, Omron's dynamic displays focused on the core pain points of current manufacturing. In the "Intelligent Innovation Applications" zone, a series of solutions deeply integrating AI, IoT, and robot technologies became the highlight. Among them, the Multi-Variety Workpiece Automatic Vibration Suppression System, designed for high-frequency production changeover needs, can automatically track workpiece weight changes and dynamically adjust parameters based on advanced algorithms, achieving high-speed, sway-free transfer. The complementary Workpiece Individual Traceability System, combining multi-axis synchronous control and on-the-fly vision technology, achieves precise tracking, real-time rejection, and subtle defect detection on high-speed production lines running at 1200 pieces per minute. Through large-capacity, cycle-synchronized data collection, it enables full-process individual tracing and root cause analysis, significantly improving quality control efficiency.

In the "Digital Driving the Future" zone, Omron prominently launched its Intelligent Production Management Platform. This platform is dedicated to breaking down data silos by integrating multi-source, heterogeneous field data, building a transparent management system across levels and processes. Acting as an "information hub," it connects with internal systems like ERP and MES, covering four main modules: production management, quality management, equipment management, and energy management. Leveraging AI algorithms, it enables predictive maintenance, quality root cause analysis, and energy consumption optimization, establishing a new management foundation for intelligent manufacturing for enterprises.

Strengthening Hardware Foundation, Co-building Industrial Ecosystem, Empowering a Sustainable Future

Omron's long-term development strategy was also clearly presented at the exhibition. In the "Strong Product Matrix" zone, it showcased the core hardware that supports the efficient collaboration of the aforementioned intelligent systems, including high-performance machine automation controllers, sensors, servo drives, and more, solidifying a robust hardware foundation for intelligent manufacturing.

Going beyond product and technology display, Omron actively engaged in building the industrial ecosystem. During the fair, the company held multiple themed speeches focusing on the "Digital & Intelligent" theme and the "High-end" production goal, sharing application achievements in sectors like semiconductors, automotive, food & daily necessities, and healthcare. Furthermore, Omron deeply participated in several concurrent CIIF forums, such as "AI New Intelligent Manufacturing, New Era of Technology" and the "PLCopen and Intelligent Manufacturing Shanghai Seminar," discussing development strategies with industry partners.

Mr. Zhu Zuojjiang, Director and General Manager of Omron Automation (China) Co., Ltd., stated that the company always centers on customer needs and actively responds to market changes. In the future, Omron will continue to be guided by its innovative "i-Automation!" manufacturing philosophy. It is committed to becoming a trusted long-term partner for Chinese customers not only by providing advanced technology but also through intelligent applications, digital driving force, and ecological collaboration, continuously injecting momentum for the manufacturing industry to achieve high-quality and sustainable development.