Against a backdrop where keywords such as “AI + logistics,” “green supply chain,” and “flexible automation” are gaining prominence, China’s logistics equipment industry stands at a critical crossroads. On one side, technological advancements are accelerating the shift toward flexible, intelligent, and green logistics systems. On the other, intense domestic competition continues to exert cost pressures across the market.

In this environment, drive and control technologies—the core enablers of logistics automation—are moving from behind the scenes to the forefront, becoming decisive factors in system performance and adaptability.

During a recent interview with gongkong®, Gao Changxing, Sales Director for the Logistics Industry at Lenze China, highlighted the dual challenges facing Chinese logistics equipment manufacturers. He noted that while the domestic market is caught in “white-hot price competition,” customers now demand more than just low cost—they seek “low cost for basic needs” alongside “high performance for international markets.”

This dual demand reflects the growing pains of an industry transitioning from “manufacturing” to “smart manufacturing.” Competing globally requires alignment with international standards in design, safety certification, software interfaces, and energy efficiency—going beyond mere supply chain cost reduction.

In response, Lenze—a German drive specialist with nearly 80 years of experience—is adopting a flexible and modular product strategy tailored to the complex and varied needs of the Chinese market.

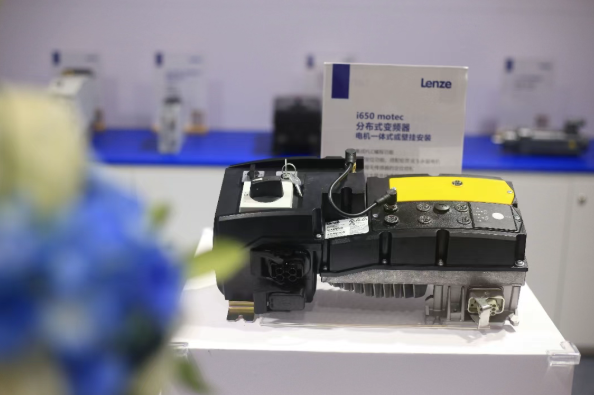

At the recent Asia International Logistics Exhibition, Lenze showcased a comprehensive range of drive solutions designed for high, mid, and low-end applications. Among them, the i-series distributed frequency converters stand out:

Lenze also unveiled its latest IE5/IE6 high-efficiency motors, which employ permanent magnet synchronous technology and sensorless control algorithms. These motors maintain ultra-high efficiency across 30%–100% load ranges, reducing energy loss by up to 60% compared to traditional IE3 motors. Compact and capable of high starting torque, they are ideal for logistics conveying systems where energy efficiency and dynamic response are critical.

Gao emphasized that Lenze’s products not only help reduce costs, save space, and shorten installation time, but also feature energy recovery functions that significantly lower operational (energy consumption).

Strategic Growth and Localization

To sustain competitiveness in China, Lenze has positioned itself not merely as an equipment supplier, but as a “reliable driving force” within the local logistics ecosystem. Its strategy combines technological leadership with deep localization—focusing on rapid response, customization, and cost adaptation.

For instance, Lenze provides tailored drives, frequency converters, and motors—including special mechanical interfaces, feedback units, and cables—for international leaders such as KUKA, enabling “close-fitting” delivery that supports both local and global projects.

A notable case is Lenze’s collaboration with the world’s largest lithium battery producer in a U.S. project with a leading automotive manufacturer. Lenze supplied over 4,000 Smart motor integrated drive units (g500 + m300 frequency converter) for formation and capacity grading processes as well as automated storage and retrieval systems. The solution helped reduce control cabinet footprint by over 70%, cut cabling by more than 80%, and supported line speeds of 16–20 m/min with 2.5-ton loads.

Beyond lithium battery, Lenze’s frequency converters and gearmotors have been deployed at scale in sectors such as tobacco, e-commerce, and beverages. These implementations demonstrate how Lenze’s localized approach—combining production, technical customization, and engineering support—is embedding the company deeply into China’s logistics equipment supply chain as a trusted solutions partner.

As the logistics industry shifts focus from single-device performance to system-wide simplicity, efficiency, and resilience, Lenze continues to leverage its innovation-driven portfolio and ecosystem collaboration to help customers navigate the deepening waters of digital transformation—both in China and beyond.