Against the backdrop of the continuous rapid development of China's e-commerce and logistics industries, there is a growing market demand for efficient, intelligent, and open logistics automation solutions. In this context, improving energy efficiency, system integration, and cost control have become key to industry upgrading. As a leader in drive and automation technology, Lenze leverages its profound technological expertise and localized innovation strategy to consistently help logistics companies tackle challenges and seize opportunities.

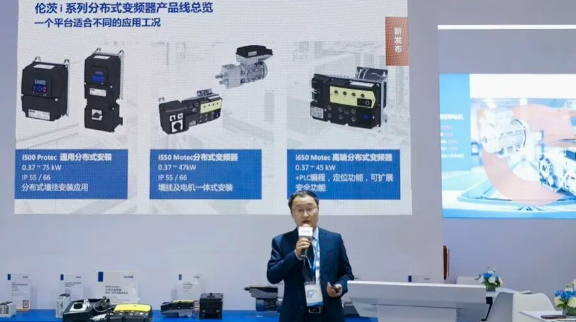

On October 28, the CeMAT Asia 2025 exhibition grandly opened at the Shanghai New International Expo Centre. Lenze hosted a new product launch at its booth W3-A2, officially introducing the i650 motec decentralized frequency converter and its supporting high-efficiency motor drive solutions to the Chinese market, attracting numerous industry experts, clients, and media representatives.

The launch event featured addresses by Jason Ha, President of Lenze East Asia; Mr. Hanke, Global Head of Logistics Industry at Lenze; and Deming Li, National Senior Sales Director of Lenze. They elaborated on Lenze's technological approach and innovation philosophy in logistics automation from three perspectives: global trends, local practice, and strategic planning. They emphasized that Lenze is committed to deeply integrating core German technology with efficient local innovation to build future-oriented drive solutions for logistics.

Technical Highlights & Live Demonstration

The newly launched i650 motec frequency converter integrates a built-in PLC, precise positioning, and expandable safety functions. It supports multiple Ethernet buses and sensorless safety control, significantly reducing energy consumption while saving space. Paired with IE5/IE6 high-efficiency motors, system losses are reduced by over 60% compared to IE3 models, with faster response times and substantially improved overall energy efficiency.

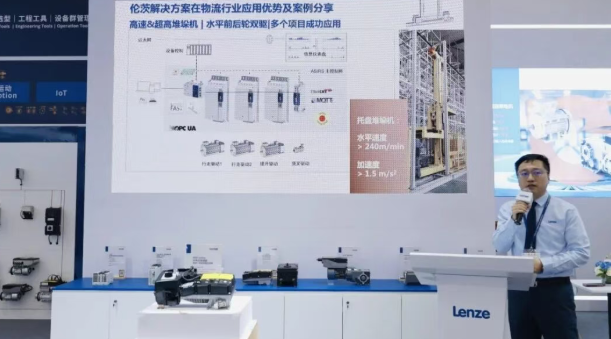

Changxing Gao, China Logistics Industry Sales Director at Lenze, introduced at the scene that this solution has already been successfully applied in several critical scenarios. For example, at Anta's Suzhou Operations Center, stacker cranes equipped with Lenze systems achieved a horizontal speed of 5.4 m/s. In a conveyor line project for a leading lithium battery manufacturer, the smart motor solution saved over 80% of cabling and significantly improved installation efficiency.

Looking ahead, Lenze will continue to focus on core logistics scenarios such as warehousing, airports, and postal parcel handling, promoting the development of drive systems towards higher efficiency, intelligence, and sustainability. Through deep localization and collaborative innovation, Lenze aims to help customers simplify engineering processes, reduce total hardware costs (with estimated savings of 20% to 50%), and support Chinese logistics companies in building technological advantages and enhancing their competitiveness in the global market.

With energy efficiency innovations and rapid response capabilities, Lenze is redefining the future path of logistics automation.