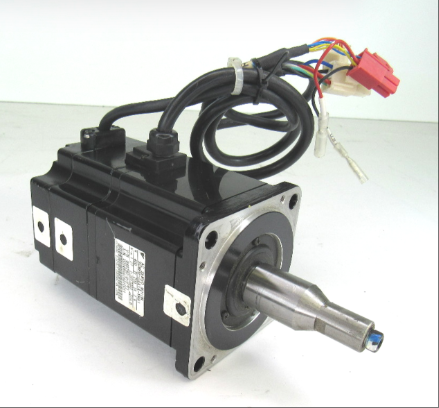

SGMPH-04A1A-YR61

The SGMPH-04A-YR61 servo motor is a high-performance compact servo motor designed specifically for industrial automation scenarios. It adopts a flat structure and permanent magnet synchronization technology, with a rated power of about 0.4 kW, suitable for 200V level three-phase power supply, supports high-speed operation (rated speed of 3000 r/min, maximum speed up to 5000 r/min), and has high dynamic response capability. It is equipped with a 13 bit incremental encoder (some models can choose a 16 bit absolute encoder), which can achieve a positioning accuracy of ± 0.01mm, meeting the high-precision requirements of trajectory tracking and repetitive positioning for precision equipment such as electronic manufacturing and semiconductor processing. The motor adopts a flange installation, and the output shaft is designed as a flat shaft (optional balance key or plunger), which is easy to connect directly with the transmission components; The protection level reaches IP65 (except for the shaft penetration part), with dustproof and waterproof capabilities, and can operate stably in an environment temperature of -10 ℃ to 40 ℃, suitable for industrial sites with high dust and humidity. In addition, this model supports collaboration with ∑ -7 series drivers and is compatible with mainstream industrial bus protocols such as EtherCAT and MECHATROLINK-III. Parameter visualization debugging and vibration suppression optimization can be achieved through SigmaWin+software. It also integrates STO safety torque shutdown function, which complies with the IEC 61800-5-2 safety standard and is suitable for scenarios that require high reliability and safety redundancy, such as joint drives for industrial robots and feed axes for CNC machine tools.

Technical specifcations for SGMPH-04A1A-YR61

Basic specifications

Rated output power: 0.4kW, suitable for low-power precision drive scenarios.

Rated voltage: AC200V, compatible with standard industrial three-phase power supply.

Rated speed: 3000r/min, with a maximum speed of 5000r/min, meeting the requirements for high-speed operation.

Protection level: IP65 (motor body), the protection level of the shaft through part may be reduced, and it needs to be configured with sealing components.

2、 Performance parameters

Rated torque: 0.318N · m, instantaneous maximum torque 3.82N · m, supports short-term overload conditions.

Torque constant: 0.349N · m/A, reflecting the linear relationship between motor electromagnetic torque and current.

Motor inertia: 0.331 × 10 ⁻⁴ kg · m ², low inertia design improves dynamic response speed.

Rated power response: 49.0 kW/s, representing the transient capability of power regulation.

Rated angular acceleration: 38500 rad/s ², reflecting high-speed start stop performance.

Mechanical time constant: 0.36ms, measuring the response speed of the motor from static to steady state.

Electrical time constant: 8.6ms, reflecting the electromagnetic transient characteristics of the armature circuit.

3、 Electrical parameters

Rated current: 2.6 Arms, instantaneous maximum current: 8.0 Arms, needs to be matched with driver overload capacity.

Encoder configuration: 13 bit incremental encoder (8192P/r), optional 16 bit absolute encoder.

4、 Mechanical and Installation

Installation method: Flange installation, supports flat shaft output (can be equipped with flat keys or plungers).

Shaft end design: The flat shaft structure is compatible with direct coupling, and an optional actuator can be configured.

Environmental adaptability: Operating temperature range of 0~40 ℃, humidity of 20%~88% (non condensing).

5、 Safety and reliability

Safety function: Integrated STO safety torque cutoff, compliant with IEC 61800-5-2 standard.

Protection mechanism: Built in overload and overheating protection, extending the lifespan of the motor.

Certification standards: CE, UL, RoHS certification to ensure compliance and safety.

6、 Communication and compatibility

Communication protocol: Supports mainstream industrial buses such as EtherCAT and MECHATROLINK-III.

Driver compatibility: compatible with ∑ -7 series drivers to achieve full closed-loop control.

Debugging software: Supports SigmaWin+parameter visualization configuration and vibration suppression optimization.

Our Services:

1、All our products are new and orginal, and of good quality

2、Our prices are very competitive.

3、 We have a large quantity in stock, so we could help the customers to get the components which are dificult to get.

4、All inquiries will be valued and will reply in 24.

Packing & Delivery:

1、100% brand New and Original Factory Seal!

2、Warranty:1 year

3、Package: Original packing with cartons.

4、Delivery time: Shipped in 3-7 days after payment

5、All the goods will be tested before shipment

More Products In Stock:

| SGDS-08A12A | SGMAH-07DAA61D | SGDH-30DE-OY | SGMGH-05DCA6F-OY | SGMEV-07DDA61-OY |

| SGMGH-30DCA6H-OY | SGMRV-13ANA-YR11 | SGMSH -15D2A6S-OY | SGMPH-04A1A-YR61 | SGMRV-37ANA-YR11 |

| SGDH-10AE | SGMSV-15D3A6F |