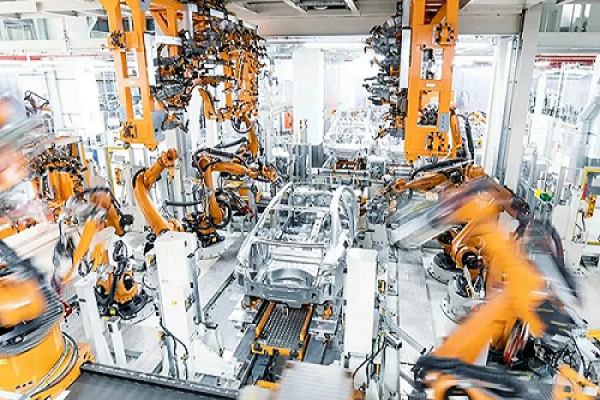

Audi has chosen Siemens S7-1500V as the core driving force for its virtual factory in its journey towards future production models, jointly drawing a grand blueprint for industrial intelligence. By streamlining device types, reducing hardware dependencies, and fully transitioning to a software driven production model, Audi is reshaping the automotive manufacturing industry with unprecedented speed, stability, and flexibility.

Reshaping the Production Landscape: A Leap from Hardware to Software

Audi's goal is clear and firm - to build a highly integrated and continuously optimized virtualized workshop, guided by "technology leads the future", and accelerate the integration of IT and OT (operational technology). Faced with the challenges of numerous equipment, high maintenance costs, and intensified network security under traditional production modes, Audi has teamed up with Siemens to embark on a journey of digital transformation in the production process.

Integrating IT and OT: A New Chapter in Workshop Automation

The Siemens SIMATIC S7-1500V virtual PLC has become the key to this transformation. It is not only a bridge connecting IT and OT, but also a core component of Audi Edge Cloud 4 Production strategy. This innovative solution draws on the efficient architecture of data centers, unifies the underlying infrastructure, and provides a powerful support platform for upper level applications. All production processes run as software in a private cloud, achieving comprehensive digitization and centralization of production management.

Practice makes perfect: Successful deployment of virtual PLC

Since the official launch of virtual PLCs in spring 2023, Audi has worked closely with Siemens to overcome numerous challenges. In January 2024, two virtual PLCs were successfully deployed at the B ö llinger H ö fe factory in Neckarsulm, marking the official entry of Audi's e-tron GT axle assembly line into the era of virtualized production. This achievement not only validates the feasibility of virtual PLC, but also lays a solid foundation for its subsequent large-scale promotion.

Advantages highlighted: comprehensive upgrade from efficiency to safety

The deployment of virtual PLC has brought many significant advantages to Audi. Employees can seamlessly transition to the new production environment without changing their operating habits; A unified infrastructure makes management more convenient and efficient, while also enhancing the level of network security protection; Quickly responding to market changes, adjusting production configurations as needed, achieving optimal allocation of resources and efficient utilization of energy.

Hand in Hand: Creating an Intelligent Industrial Future Together

The cooperation between Siemens and Audi is not limited to the technical level, but also involves multiple dimensions such as organizational structure and process optimization. By establishing a dedicated Edge Cloud 4 Production team, both parties have achieved close collaboration between IT and OT personnel, overcoming various challenges encountered during the implementation process. As the project progresses, more and more successful experiences and organizational operating models will be accumulated and applied to future production.

Looking ahead, Siemens S7-1500V and its virtualized production model will continue to lead the industrial trend. With the joint efforts of industry giants such as Siemens and Audi, a more intelligent, flexible, and efficient industrial era is accelerating.