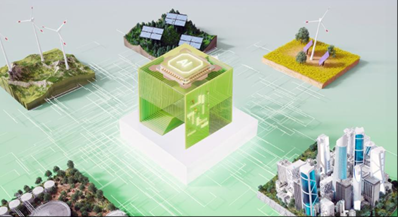

Schneider Electric Reshaps the Industrial Future with Innovative Technologies: AI and Open Automation Drive a New Paradigm of Green Intelligent Manufacturing

At a critical juncture of global industrial transformation towards high-end, digital, and green industries, Schneider Electric continues to lead industry change with its profound expertise in energy management and industrial automation. In 2025, this multinational giant with nearly 200 years of history will further consolidate its position as a core promoter of global industrial transformation through technological innovation, ecological cooperation, and localization strategy.

● AI technology deeply empowers industrial scenarios, achieving dual breakthroughs in energy efficiency and sustainability

Schneider Electric deeply embeds artificial intelligence technology into the entire industrial production process, covering multiple scenarios such as production scheduling prediction, equipment control optimization, and process energy conservation. For example, its AI based energy-saving solution for cold stations dynamically adjusts the operating parameters of the refrigeration system by analyzing environmental data and equipment status in real-time, helping customers achieve a 15% -30% reduction in energy consumption. In the field of automotive painting, AI algorithms optimize spray paths and material ratios, increasing paint utilization by 10% while reducing VOC emissions.

In 2025, Schneider Electric announced a strategic cooperation with Nanjing Keyuan Intelligence to carry out joint innovation in the full scenario of energy "source network load storage" and industrial software fields. Both parties rely on Schneider's EcoStruxure architecture and platform, combined with Nanjing Keyuan's digital experience in process industry, to jointly develop intelligent control solutions suitable for new energy generation, energy storage systems, and industrial microgrids, helping customers build zero carbon parks.

● Upgraded open automation platform, further enhancing flexible production and supply chain resilience

As a pioneer in the field of open automation, Schneider Electric's EcoStruxure open automation platform V24.1 version, launched in 2024, has been implemented in over 300 factories worldwide. This platform decouples hardware and software, supports interconnection and intercommunication of devices from multiple suppliers, shortens the production line renovation cycle by 40%, and increases equipment utilization by 25%. In the Chinese market, Schneider Electric's Shanghai factory has achieved deep integration of computing power, network, and control through this platform, building a flexible production line that supports multi variety and small batch production, and reducing order delivery cycles by 30%.

Schneider Electric has launched a supply chain resilience solution based on digital twins to address supply chain challenges. This solution integrates supplier data, logistics information, and production plans, analyzes potential risks through AI simulation, and helps customers develop emergency plans in advance. In 2024, a global automotive parts company adopted this plan, resulting in a 50% increase in response speed to supply disruptions and an 18% increase in inventory turnover.

● Localized innovation accelerates, Chinese R&D center becomes global technology engine

Schneider Electric has been deeply rooted in the Chinese market for 37 years and has formed a full chain layout of "research and development production sales service". Among its five research and development centers located in Shanghai, Shenzhen, Xi'an, Beijing, and Wuxi, the IA China Hub for Industrial Automation will be upgraded to one of the four core research and development centers worldwide in 2022, undertaking localized development tasks for open automation platforms, AI algorithms, and industry solutions.

In 2024, IA China Hub will launch the Lexium 18 series servo drives and Easy Harmony FT6 stainless steel touch screen designed specifically for high-temperature and high humidity environments in the Asian market, with a protection level of IP69K. Among them, the Lexium 18 series supports both EtherCAT and Profinet protocols, with a response time reduced to 0.1 milliseconds and an accuracy of ± 0.01%. It has been applied in high-precision manufacturing scenarios such as photovoltaic silicon wafer cutting and lithium battery coating.

● Deepening ecological cooperation and jointly building new industrial quality productivity

Schneider Electric shares technical resources and industry experience with over 200 system integrators through the "Industrial SI Alliance" global project. In China, this project has helped more than 30 companies connect to the global supply chain system. For example, a domestic packaging machinery enterprise obtained European market access certification through Schneider's ecological collaboration, and its export value of intelligent packing lines increased by 200% year-on-year.

In 2024, Schneider Electric will add two new "lighthouse factories" - the Monterey 1 factory in Mexico and the Putuo factory in Shanghai. These two factories have achieved a 22% increase in production efficiency and an 18% reduction in carbon emissions per unit product by deploying AI predictive maintenance, digital twin simulation, and energy management systems. Its experience has been replicated in over 150 factories worldwide, driving Schneider Electric to remain at the top of Gartner's "Top 25 Global Supply Chains" for two consecutive years.

● Future Outlook: Promoting Global Industrial Zero Carbon Transformation through Technology Inclusion

Facing the new opportunities brought by the integration of AI and industrial Internet, Schneider Electric plans to embed AI technology into 80% of industrial products and solutions by 2027. At the same time, the company promises to achieve operational carbon neutrality by 2030 and full value chain carbon neutrality by 2050.

The future of industry lies in openness, collaboration, and sustainability, "said Barbara Frei, Global Executive Vice President of Schneider Electric." China is not only our source of innovation, but also a barometer of global industrial transformation. We will continue to increase our R&D investment in China and work with ecological partners to build a green and intelligent industrial ecosystem

Driven by technological iteration and market demand, Schneider Electric is providing global industrial customers with a full lifecycle service from consulting to implementation through a "technology+ecology" dual wheel model, helping them overcome cycles and achieve high-quality development.