August 26, 2025 – Rockwell Automation announced today that its system integration partner Tri Tech Automation ("Tri Tech") has successfully leveraged Rockwell's Unified Power and Process Control Solution to ensure the timely commissioning of a newly built cheese and whey ingredient production facility. Located in Missouri, USA, and commissioned by a leading food enterprise, the project addressed rapid industry growth demands while overcoming two critical challenges: a tight 18-month timeline requiring strict milestone adherence and complex multi-vendor coordination that risked inefficiencies and cost overruns under traditional siloed control systems.

Unified Solution Breaks Through Pain Points, Integrated Architecture Optimizes Entire Workflow

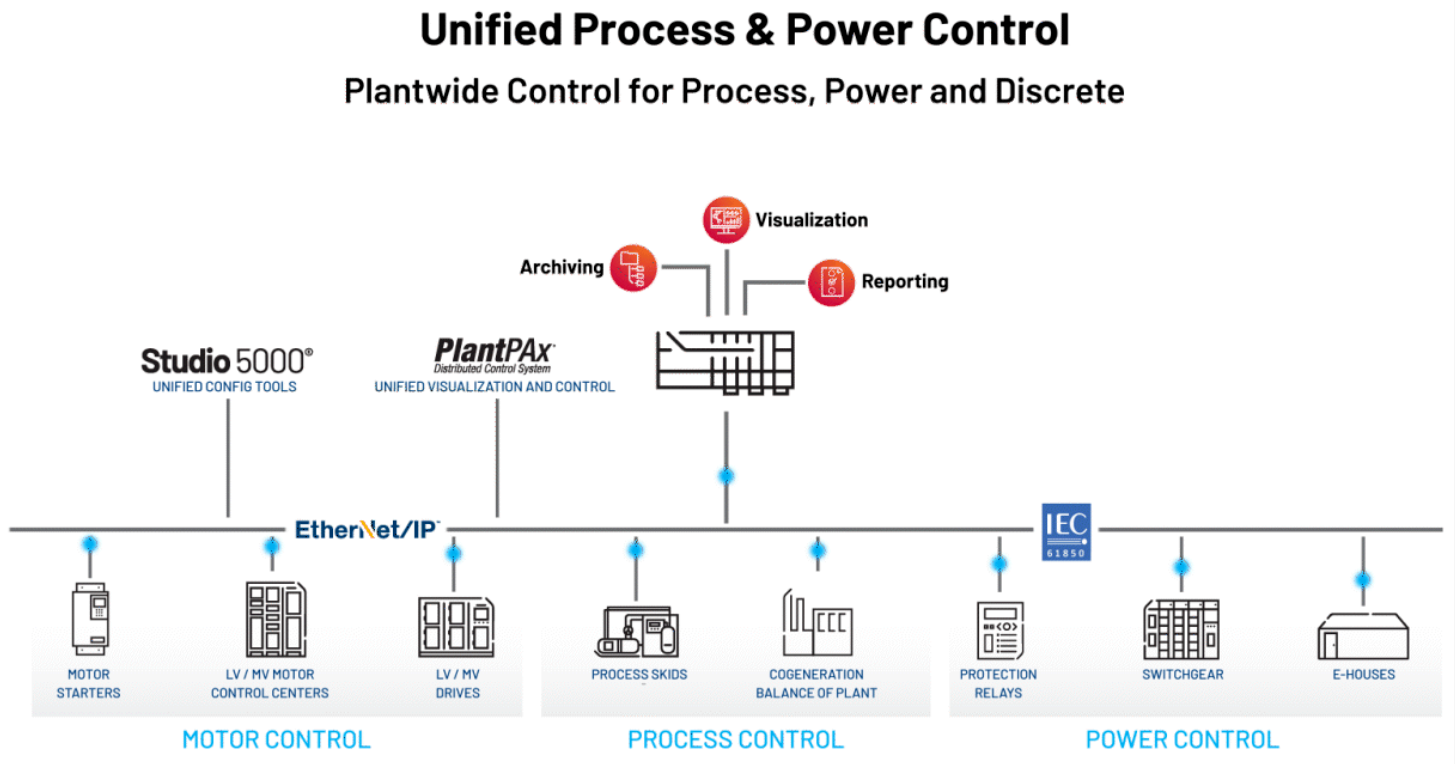

Tri Tech deployed Rockwell's Unified Power and Process Control Solution to integrate motor control centers, variable frequency drives, I/O modules, and process gateways into a single network. This innovation marked the first time process control, safety control, energy management, and electrical systems were unified under a single architecture. The solution delivered three key breakthroughs:

Ryan Williams, Tri Tech's Sales and Marketing General Manager, stated: "From day one, the milk delivery deadline was fixed—every day counted. We secured Rockwell's configure-to-order solution early, reserved critical spare parts, and adopted strategies like ordering all drives in rack-top configurations to maintain flexibility and keep the project on track."

Digital Foundation Empowers Long-Term Operations, Industry Benchmark Impact

The facility is now fully operational, with Tri Tech providing remote support to continuously optimize processes and reduce utility costs. Bruce Hall, Rockwell's North America Solutions Design Director, emphasized: "The value of our unified solution extends beyond project delivery—it future-proofs expansion. By optimizing the OT network design, we've built a sustainable digital core for the client."

This case is hailed as a model for industrial automation empowering food manufacturing. Rockwell's Q3 2025 earnings report highlights a 23% YoY growth in its software and control division, with margins rising to 31.6%, underscoring market demand for integrated solutions. Analysts note that the "integrator + tech leader" collaboration model offers a replicable success path for global mega-projects, particularly in food & beverage and life sciences.

Industry Impact

The project validates the unified architecture's advantages in reducing complexity, risk, and costs, setting a new standard for digital transformation in food manufacturing. As industrial AI and cloud technologies advance, Rockwell's "Technology Trio" strategy—automation, data-driven insights, and AI empowerment—is driving enterprises to transition from "on-time startup" to "sustained operational excellence."

This collaboration not only resolved immediate challenges but also laid a digital foundation for future efficiency upgrades and cost optimizations—a testament to how integrated solutions and strategic partnerships are reshaping global manufacturing.