On the path of pursuing efficient operations, factory digitization has become an industry consensus. For a long time, automation systems such as PLC (Programmable Logic Controller) and HMI/SCADA (Human-Machine Interface/Supervisory Control And Data Acquisition) have played a crucial role in controlling equipment operation and enhancing productivity. However, as the benefits of traditional digital means gradually saturate, the demand for factory digital transformation has become increasingly urgent.

Despite the industry's progress in digital transformation, leveraging the Internet of Things (IoT) to collect vast amounts of data for predictive maintenance, the massive real-time data generated by IoT devices has become a major challenge for manufacturers. According to International Data Corporation (IDC) estimates, by 2025, there will be 41.6 billion connected IoT devices generating up to 79.4 zettabytes of data. Faced with such a huge amount of data, manufacturers often struggle to cope, resulting in extremely low data utilization rates and difficulty in meeting various demands.

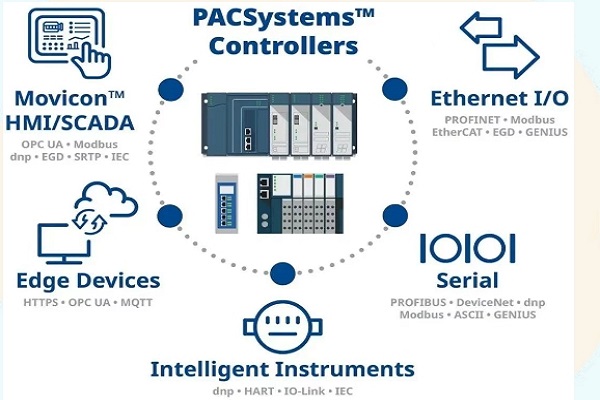

Against this backdrop, Emerson stands out with its edge data analytics solution. This solution offers high interoperability and ease of use, enabling communication with factory floor devices and monitoring systems using standard communication protocols, tightly connecting people, machines, and data. Through powerful data analytics and real-time control technology, Emerson can collect, analyze, and filter operational data and send it to the cloud, providing manufacturers with real-time insights into production.

Emerson's PACSystems™ RX3i edge controller meets the demands for high-performance deterministic control and computing, running PACEdge™ software through advanced virtualization technology to collect, store, analyze, and visualize data at the edge close to the control system. Data visualization, with its intuitiveness, allows staff to quickly understand issues, accelerate decision-making, and facilitate online collaboration among teams from different departments and functions, breaking down organizational islands.

Furthermore, Emerson leverages its powerful Movicon.NExT™ automation platform to extend visual data information from fixed central control rooms to mobile devices, further enhancing personnel collaboration. When the system detects a problem in real-time, personnel with multiple skills in operation and maintenance can carry mobile HMIs to quickly rush to the production line to troubleshoot and resolve issues on the spot, significantly improving factory operation and maintenance efficiency.

Emerson's series of innovative initiatives not only help manufacturers fully analyze and utilize data, enabling intelligent decision-making and reducing operational risks and costs, but also drive the wave of digital transformation throughout factories. In the future, as more companies join the digital transformation ranks, Emerson's edge data analytics solution will undoubtedly become an important force leading industry development.