Amidst the global wave of intelligent manufacturing, the paper industry, as a traditional foundational sector, is facing an urgent need for digital transformation. On one hand, the potential risks of mechanical injuries during the operation of paper-making equipment constantly threaten the safety of operators. On the other hand, the complex energy consumption structure has made it a pressing challenge for enterprises to achieve precise control over energy consumption and effective cost accounting. Additionally, the lack of predictive maintenance for equipment leads to frequent unplanned shutdowns during production, severely impacting production efficiency and product quality. In this context, paper-making enterprises urgently need to leverage advanced technologies and solutions to realize intelligent upgrades and digital transformation of their production processes, thereby enhancing their core competitiveness.

Festo's Innovative Solutions Step In, Directly Addressing Industry Pain Points

Facing the myriad difficulties in the paper industry, Festo, a global leader in the field of automation technology, has launched a series of targeted solutions with its profound technological accumulation and innovative capabilities, injecting strong impetus into the digital transformation of the paper industry.

Rock-Solid and Worry-Free Operation: Festo Builds a Strong Production Safety Line of Defense

In terms of precise control over web tension, Festo's VPPM proportional pressure valve demonstrates outstanding performance. Whether producing delicate and thin yarn films or thick and sturdy cable paper rolls, the VPPM ensures smooth operation of the web under highly uniform tension with its flexible and precise pressure control capabilities. Through a kinetic energy compensation mechanism, it further enhances the safety of the production process, establishing a reliable safety barrier for subsequent production steps. Moreover, the VPPM supports direct reading of process data, enabling transparent data traceability and providing strong support for the enterprise's production management and quality control.

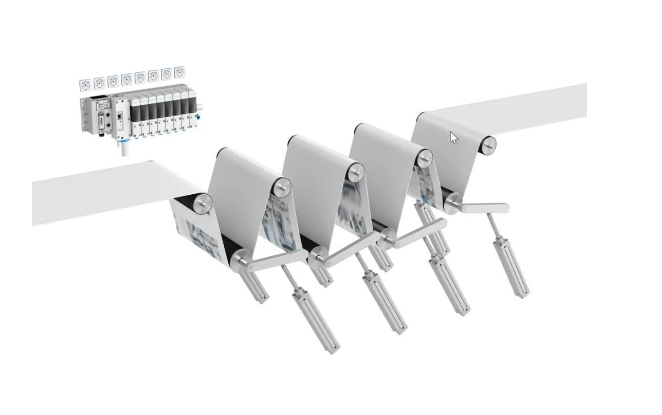

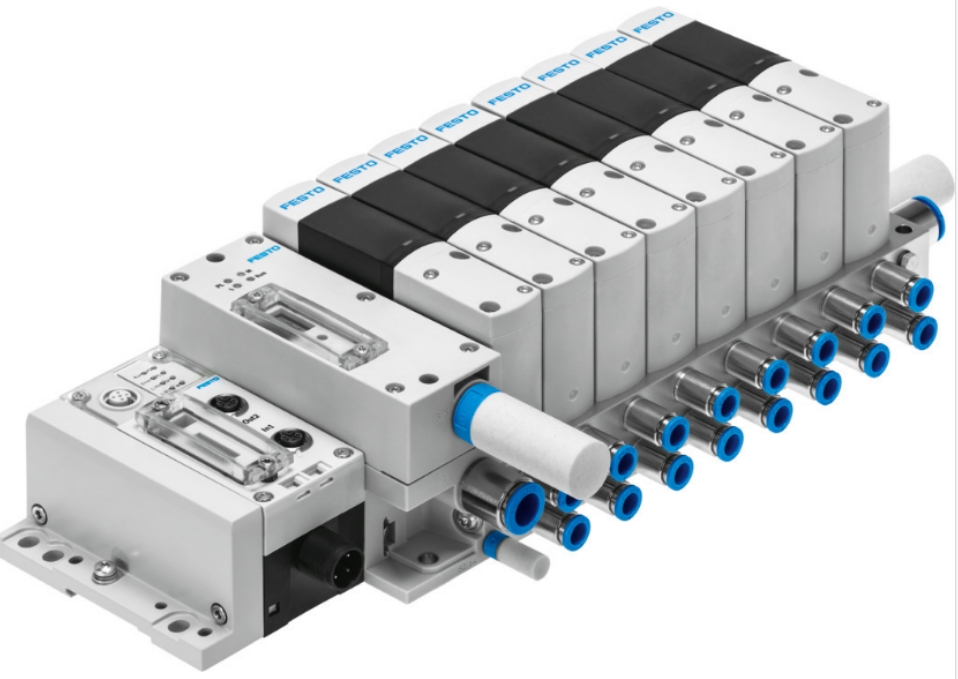

Meanwhile, Festo's digital control terminal VTEM's multi-channel control technology brings great convenience to enterprises' production programming. With this technology, enterprises can control up to 16 cylinders simultaneously using just one hardware device, easily accomplishing programming tasks for different products, significantly improving production efficiency and flexibility.

As a core component for functional conversion of electrical safety, Festo's soft start/quick exhaust valve MS6-SV plays a crucial role in ensuring the safe and continuous operation of production lines. When an emergency stop is triggered, the MS6-SV can instantly cut off the power supply to key components, preventing the escalation of accidents. After the fault is eliminated, the system achieves a safe restart through progressive loading, effectively reducing production risks.

Immediate Monitoring for Energy Conservation and Cost Reduction: Festo Assists Enterprises in Green Development

Festo's digital energy-saving module MSE6-C2M serves as a capable assistant for intelligent monitoring of automated production lines. This module can monitor air consumption in real time and automatically maintain pressure after production stops, effectively avoiding energy waste caused by leaks. Through fieldbuses, the MSE6-C2M can upload local data such as pressure and flow to PLCs or the cloud, facilitating data sharing and lean operation and maintenance for enterprises. Its integrated pneumatic air supply treatment unit comprehensively optimizes compressed air, which serves as an energy carrier. It intelligently identifies machine downtime and leaks, and is equipped with measurement, control, and diagnostic functions, providing strong support for energy optimization in the paper industry and vigorously promoting enterprises' energy conservation, emission reduction, and "green upgrades."

Proactive Predictive Maintenance for Quality and Efficiency Improvement: Festo Ushers in a New Era of Intelligent Production

Festo's AX artificial intelligence solution deeply integrates AI technology, combining functions such as digital technology, automation equipment, and real-time data analysis to bring about all-round changes to automated production lines. Leveraging the digital concept of predictive maintenance, Festo AX can detect potential equipment issues early, avoiding equipment downtime and ensuring production continuity. Its efficient and user-friendly visual operation interface comprehensively simplifies maintenance and repair work, reducing enterprises' operation and maintenance costs. Meanwhile, the predictive quality management function ensures high-quality product output, helping paper-making equipment achieve quality and efficiency improvements throughout its entire lifecycle and creating new business models and development opportunities for enterprises.

Festo's exploration and practice in the field of the paper industry's digital transformation not only solve many current challenges faced by paper-making enterprises but also point the way forward for the industry's future development. With continuous technological progress and innovation, Festo will continue to delve deep into the paper industry, constantly optimizing and improving its solutions. Collaborating hand in hand with paper-making enterprises, Festo will jointly drive the industry's intelligent upgrades and sustainable development. With Festo's assistance, the paper industry is expected to achieve significant improvements in production efficiency, notable reductions in energy consumption costs, and steady enhancements in product quality, gaining new advantages in the fierce global manufacturing competition and marching towards a smarter, more efficient, and greener future.